Silvering can be a problem for photography and fine art, but one that can be solved. Drytac’s Gilbert Espinosa explains how to eliminate these silvery lines.

Authored by Gilbert Espinosa, Territory Manager for West Coast Region, Drytac

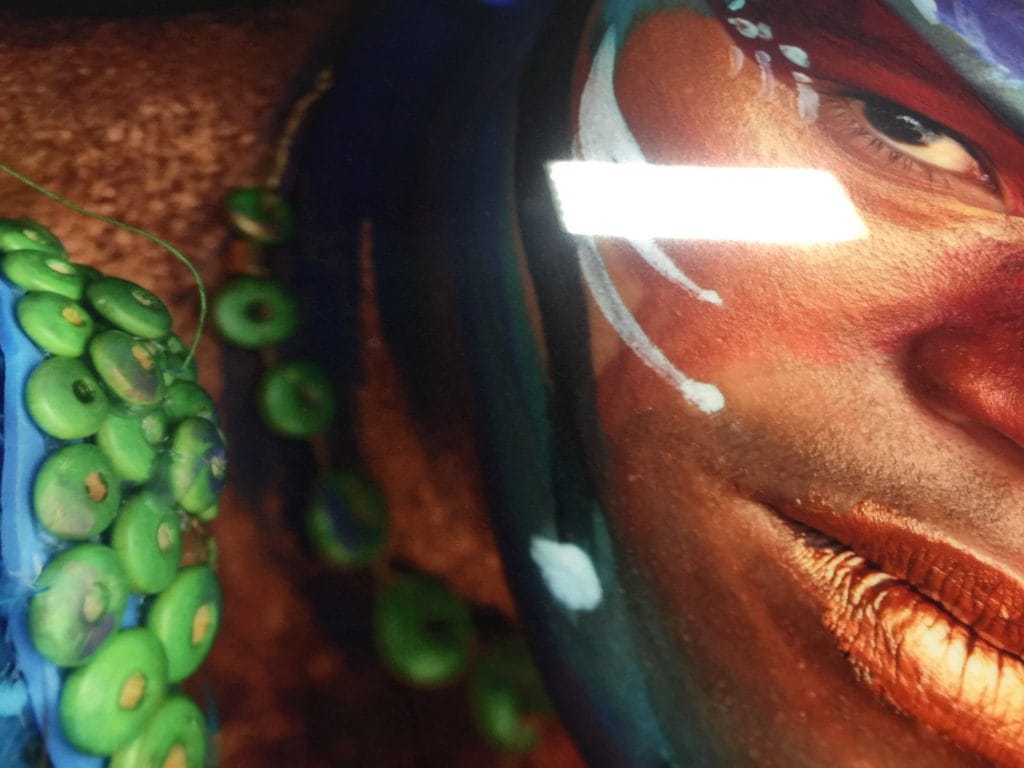

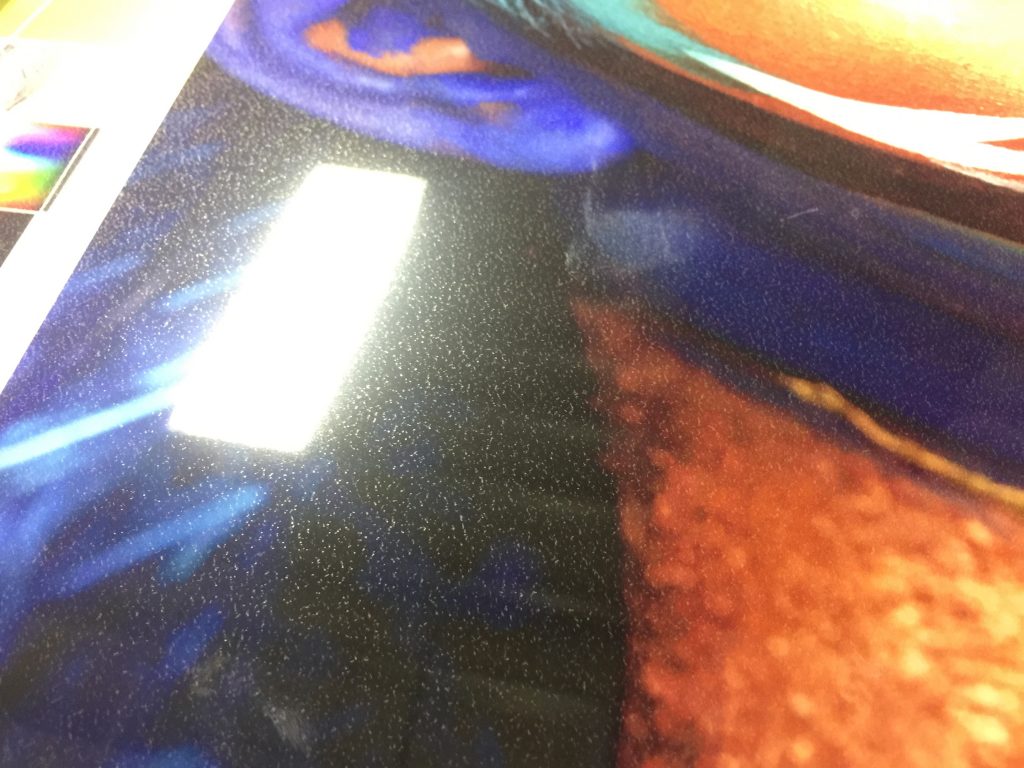

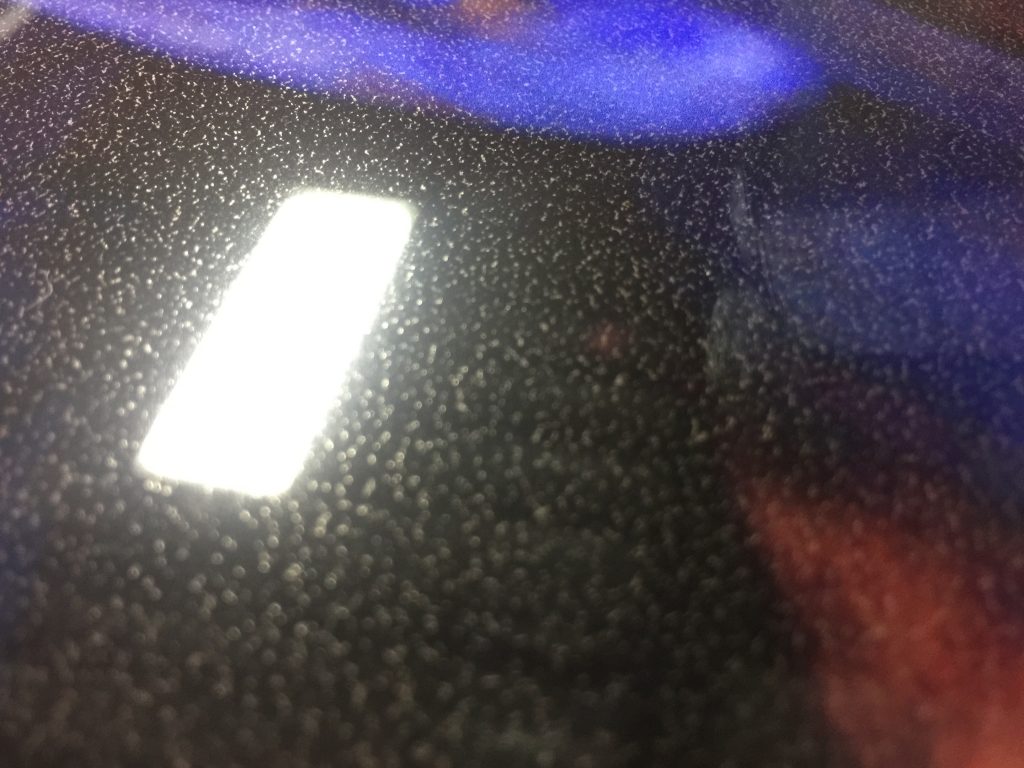

Silvering is a common issue that occurs when laminating a printed job. It’s caused by tiny bubbles of air getting trapped under the lamination, creating the appearance of hazy or silver reflective lines. It may go unseen on lighter media or light-colored printed areas, but can be far more obvious on darker colored or black images. In the photography and fine art sectors, silvering can be a problem – but one that can be solved.

First, it’s important to identify the cause of silvering. Not applying appropriate roller pressure, laminating too fast or using a media with an uneven surface – for instance paper with fibres or other media with a coarse or slightly coarse surface – may result in these silvery lines.

Silvering may also occur following wet out, the process of adhesives flowing out over the media and ink, which takes about twelve to 24 hours. Eco-solvent inks generally lay down smoothly on the surface of the media, so when the adhesive wets out it fills the area fairly evenly. UV inks, by comparison, lay down significantly less evenly, so when the adhesive flows out there are uneven areas or surfaces that are not covered with adhesive, potentially altering the graphic’s appearance.

If you are a user of UV inks, it is possible to avoid the issue of silvering by using an overlaminate product with a heavier than standard coat weight, as its adhesive can fill in the areas of uneven inks. This is especially true if the media is also uneven, such as a canvas or fibre-based product. Another factor can be the type of adhesive; softer adhesives flow out better and cover uneven areas better than harder adhesives.

Sometimes adhesion onto UV inks is an issue. Performing tests on UV inks for adhesion, peeling and silvering is recommended with a selection of different media and laminate products. It may well be possible to achieve an excellent finish by changing the combination of products rather than having to invest in another new type of ink chemistry.

If silvering is still an issue, one solution is using a matte overlaminate. The silvering is still there but is more difficult to see thanks to the matte finish; a glossy product would be more eye-catching. Drytac Protac Anti-Scratch Matte is a monomeric calendared PVC laminating film with an anti-scratch matte finish, which is coated on one side with a high-coat weight adhesive. It’s ideal for laminating over UV inks as well as eco-solvent and latex prints. Protac Anti-Scratch Matte is part of Drytac’s outstanding fine art and photography overlaminate range, which also includes Protac High Gloss and Protac High Gloss HD. In the UK and Europe, a line of high coat weight films are available, ideal for UV printed output. They include, Protac Glossy HCW UV, Protac Anti-Scratch Matte HCW UV and Protac Anti-Graffiti UV HCW. Drytac’s Interlam Pro Pressure Sensitive Overlaminating Films add depth and detail to a variety of flexible media substrates while simultaneously preventing the occurrence of silvering during lamination. There are many other options on the market that can add an incredible finish to graphics – take a look to see which is best for you.

Please reach out to one of our Drytac experts and we’d be happy to help you find the proper solution for your application.